Machining Components Lifter

Brand Name:Hamsan Tooling

Mold Base:LKM;HASCO;DME,etc

Mold Material:NAK80

Tolerance:+/-0.002mm

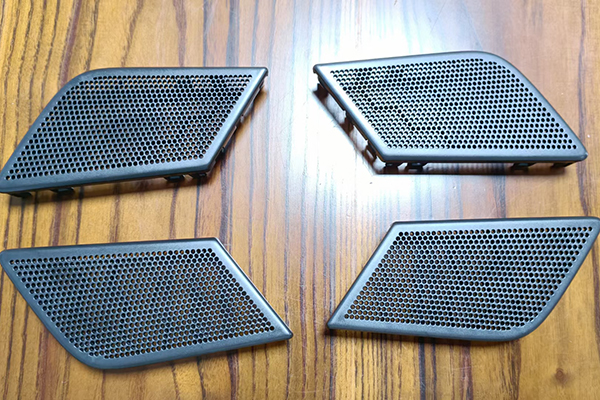

Shaping Mode:Plastic Injection Mold

Design Software:AutoCAD;NX;ProE

Packaging Details:Wooden case

Delivery Time:12 days manufacturing lead time

Products Details

Custom Machining Mold Components Lifter In Injection Molding

Hamsan Tooling has been manufacturing mold components and accessories since 2004. HST Mold prides itself on its in-house design and fabrication. We employ highly skilled professional operators to operate our drill presses, CNC machines, EDM machines, proprietary mirror EDM machines and die polishers.

Project Management:

Product DFM ⇒ Mold Design ⇒ Material Preparation ⇒ CNC Machining ⇒ EDM Machining ⇒ Grinding and Drilling Machining ⇒Wire Cutting ⇒ Polishing ⇒ Mold Fitting⇒ Mold Trail ⇒ Sample Inspection ⇒ Sample Approved ⇒ Mass Production ⇒ Mold(Product) Packing ⇒ Mold Delivery ⇒ After Sale Service

Why Choose Us:

1. Hamsan was founded in 2006, Cover an area of 5000 sqms Plant; Provide OEM/ODM Service

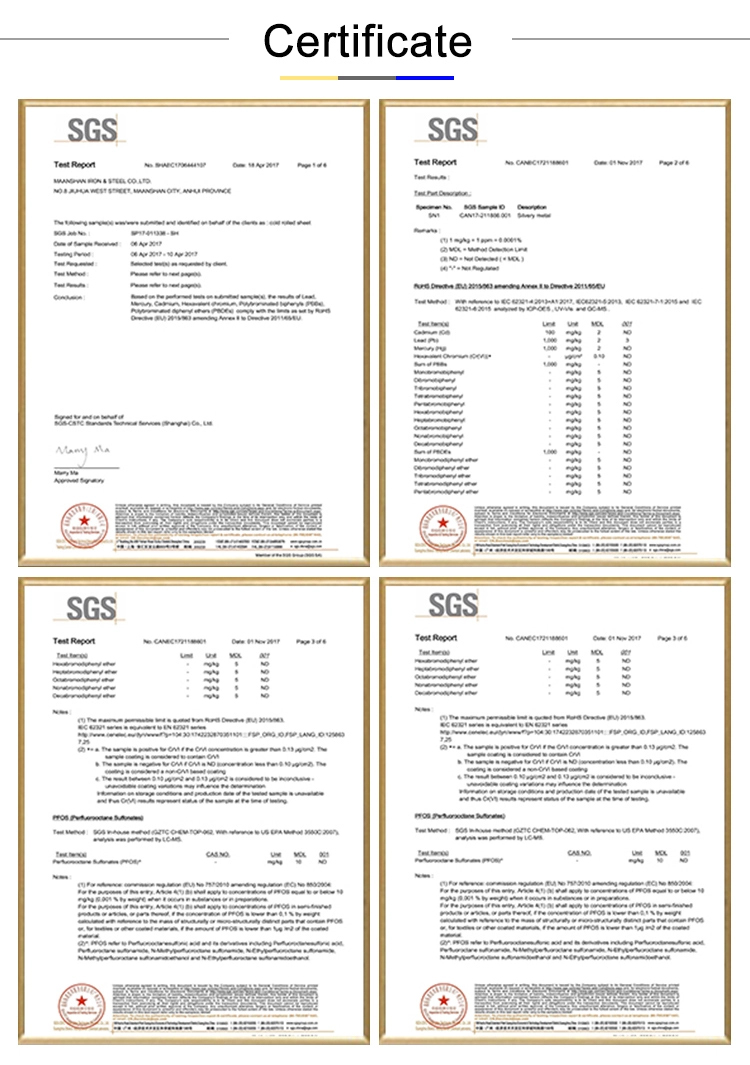

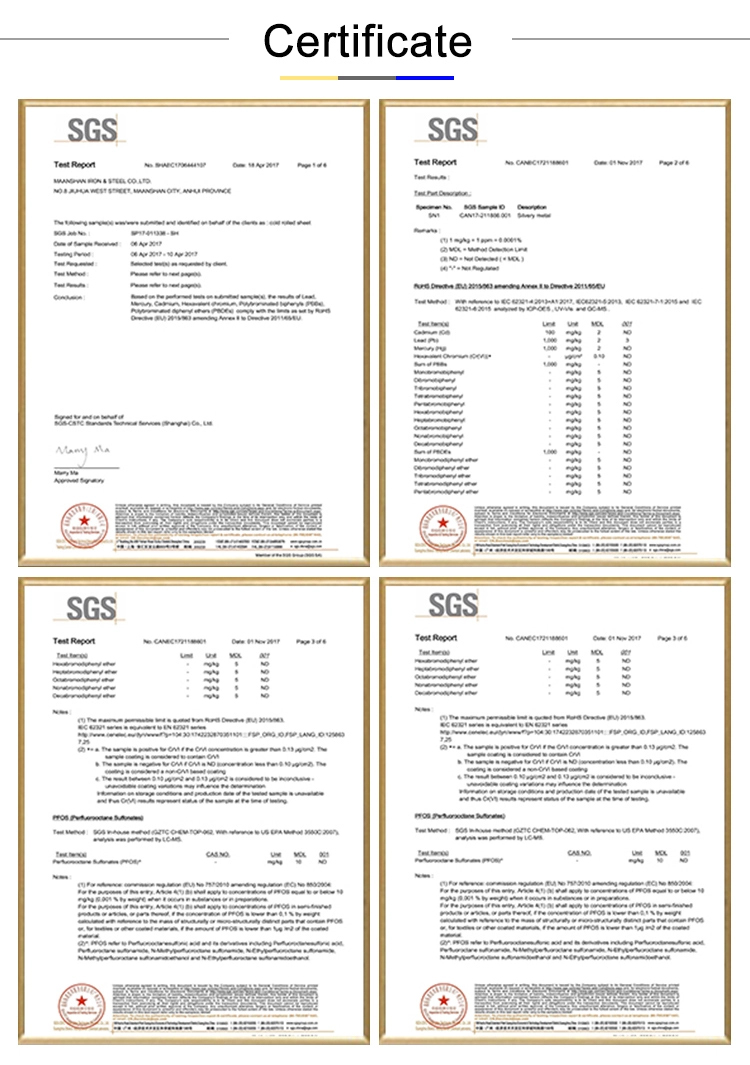

2. Certified by ISO90001, SGS,CE,UL etc

3. Over 15 years experience in Mold Making & Plastic Injection Parts Mass Production

4. Integrating R&D, QC System & Marketing Sales.

5. One-stop Service of Custom mold design from Initial drawing design, Material selection assistance, Mold structure/Mold flow analysis, Trial & mass production to Final mold assembly & shipment.

Product Description:

Product name: Precision Moulds Core supplier

Mould Material: P20,P20H,718,718H,738,738H,2316,M300,S136,S136H,NAK80,CR12,CR12MOV,SKD11,

DF-2,SKS3,D2,SLD,DC53,H13,SKD61,2344,8407,HD,8418,FDAC,M2,SKH-9,SKH-51,M35

Main Technology: Milling, grinding, CNC, EDM, wire cutting, carving, EDM, lathes, surface Finish, etc.

Base material: P20, 2738, 2344, 718, S136, 8407, NAK80, SKD61, H13

Product Material: ABS, PP, PC, PA6, PA66, TPU, POM, PBT, PVC,HIPS, PMMA, TPE, PC/ABS, TPV,

Main Technology: Milling, grinding, CNC, EDM, wire cutting, carving, EDM, lathes, surface Finish, etc.

Equipment: CNC, EDM, Cutting off Machine, plastic machinery, plastic part, etc

Mould Cavity: One cavity, multi-cavity or the same different products be made together

Runner System: Hot runner and cold runner

Finish: Pitting the word, mirror finish, matte surface, striae

Mold Life: 300-500K shots

Mould Precision: +/-0.05mm--+/-0.1mm

Hamsan Tooling has been manufacturing mold components and accessories since 2004. HST Mold prides itself on its in-house design and fabrication. We employ highly skilled professional operators to operate our drill presses, CNC machines, EDM machines, proprietary mirror EDM machines and die polishers.

Project Management:

Product DFM ⇒ Mold Design ⇒ Material Preparation ⇒ CNC Machining ⇒ EDM Machining ⇒ Grinding and Drilling Machining ⇒Wire Cutting ⇒ Polishing ⇒ Mold Fitting⇒ Mold Trail ⇒ Sample Inspection ⇒ Sample Approved ⇒ Mass Production ⇒ Mold(Product) Packing ⇒ Mold Delivery ⇒ After Sale Service

Why Choose Us:

1. Hamsan was founded in 2006, Cover an area of 5000 sqms Plant; Provide OEM/ODM Service

2. Certified by ISO90001, SGS,CE,UL etc

3. Over 15 years experience in Mold Making & Plastic Injection Parts Mass Production

4. Integrating R&D, QC System & Marketing Sales.

5. One-stop Service of Custom mold design from Initial drawing design, Material selection assistance, Mold structure/Mold flow analysis, Trial & mass production to Final mold assembly & shipment.

Product Description:

Product name: Precision Moulds Core supplier

Mould Material: P20,P20H,718,718H,738,738H,2316,M300,S136,S136H,NAK80,CR12,CR12MOV,SKD11,

DF-2,SKS3,D2,SLD,DC53,H13,SKD61,2344,8407,HD,8418,FDAC,M2,SKH-9,SKH-51,M35

Main Technology: Milling, grinding, CNC, EDM, wire cutting, carving, EDM, lathes, surface Finish, etc.

Base material: P20, 2738, 2344, 718, S136, 8407, NAK80, SKD61, H13

Product Material: ABS, PP, PC, PA6, PA66, TPU, POM, PBT, PVC,HIPS, PMMA, TPE, PC/ABS, TPV,

Main Technology: Milling, grinding, CNC, EDM, wire cutting, carving, EDM, lathes, surface Finish, etc.

Equipment: CNC, EDM, Cutting off Machine, plastic machinery, plastic part, etc

Mould Cavity: One cavity, multi-cavity or the same different products be made together

Runner System: Hot runner and cold runner

Finish: Pitting the word, mirror finish, matte surface, striae

Mold Life: 300-500K shots

Mould Precision: +/-0.05mm--+/-0.1mm